PREMIUMPACK uses EVOH

Technological protection for maximum shelf life

All PREMIUMPACK packaging for meat and sausage products has an EVOH layer which acts as an oxygen barrier in the form of high-barrier granules. With EVOH packaging, nutrients contained in food are effectively protected against bacteria on a long-term basis. The packaged products stay fresh throughout the supply chain and even after long periods of storage.

What is EVOH?

EVOH is an ethylene vinyl alcohol polymer that mainly consists of carbon, oxygen and hydrogen. The EVOH film is used in our multilayer technology as a barrier layer and protective layer and is of central importance in the food packaging industry.

The advantages of EVOH packaging

Why PREMIUMPACK relies on EVOH film in multilayer technology

Effective barrier against gases

The sophisticated molecular, crystalline structure makes EVOH an extremely effective and powerful barrier against oxygen and other gases such as nitrogen, carbon dioxide and helium. The supply of oxygen is almost completely cut off.

Significantly longer shelf life

Used in our packaging products made of multilayer structures, protective films based on EVOH extend the shelf life of meat, sausage and cheese products to a maximum. Compared to conventional standard LPDE films, EVOH has a 10,000 times higher gas barrier.

Reduces the need for preservatives

The longer shelf life of the products means that we don’t have to use preservatives as much. These are sometimes completely superfluous.

Makes products visually more attractive

Using EVOH in combination with other material components contributes to advantageous material properties.

Guaranteed food freshness

The taste, smell, colour and freshness of the packaged products are optimally preserved by using EVOH.

Environmentally friendly

The packaging materials from PREMIUMPACK help to reduce waste and thus make a sustainable contribution to environmental protection.

Reduced use of raw materials

Only a few micrometres of the material are needed to achieve the valuable barrier function. This means using EVOH leads to a reduction in raw material consumption and helps to conserve our natural resources.

High safety factor

EVOH does not contain any chlorine, dioxins, metals or other elements that can cause endocrinological diseases and thus brings a significant gain in safety for the consumer.

EVOH technology in detail

Barrier properties of EVOH compared to other materials

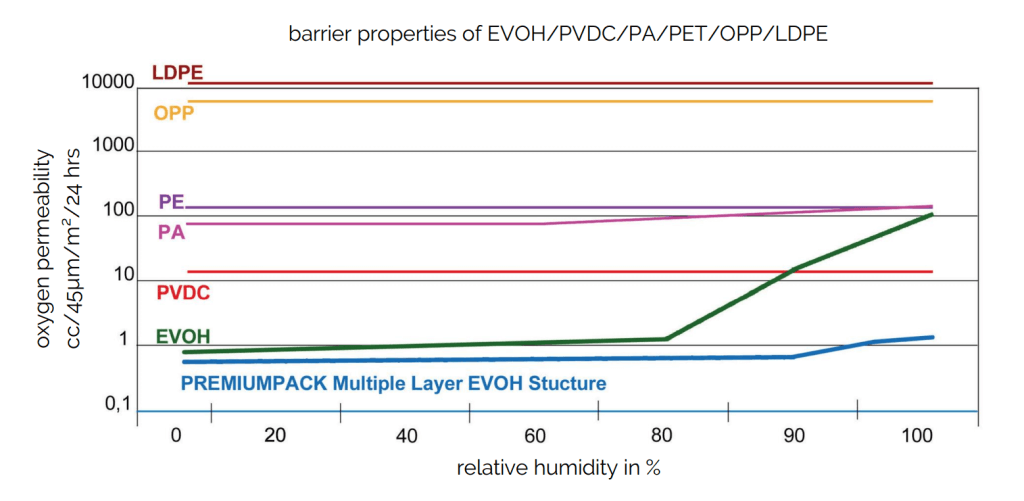

The effect of EVOH is precisely visible in the graph:

The oxygen permeability on the Y-axis shows how many cubic metres of oxygen can penetrate one square metre of film within 24 hours. The different barrier levels from low barrier (LDPE, OPP) to medium barrier (PET, PA, PE) to high barrier structures (PVDC, EVOH) are shown in comparison.

It becomes clear that EVOH has the strongest oxygen barrier under dry conditions.

By using multilayer technology to manufacture our packaging products, the EVOH layer is protected from moisture by other layers and offers the ultimate oxygen barrier – even under extremely humid conditions inside or outside the packaging.

Would you like to find out more?

Please contact us. We look forward to having a technical discussion.